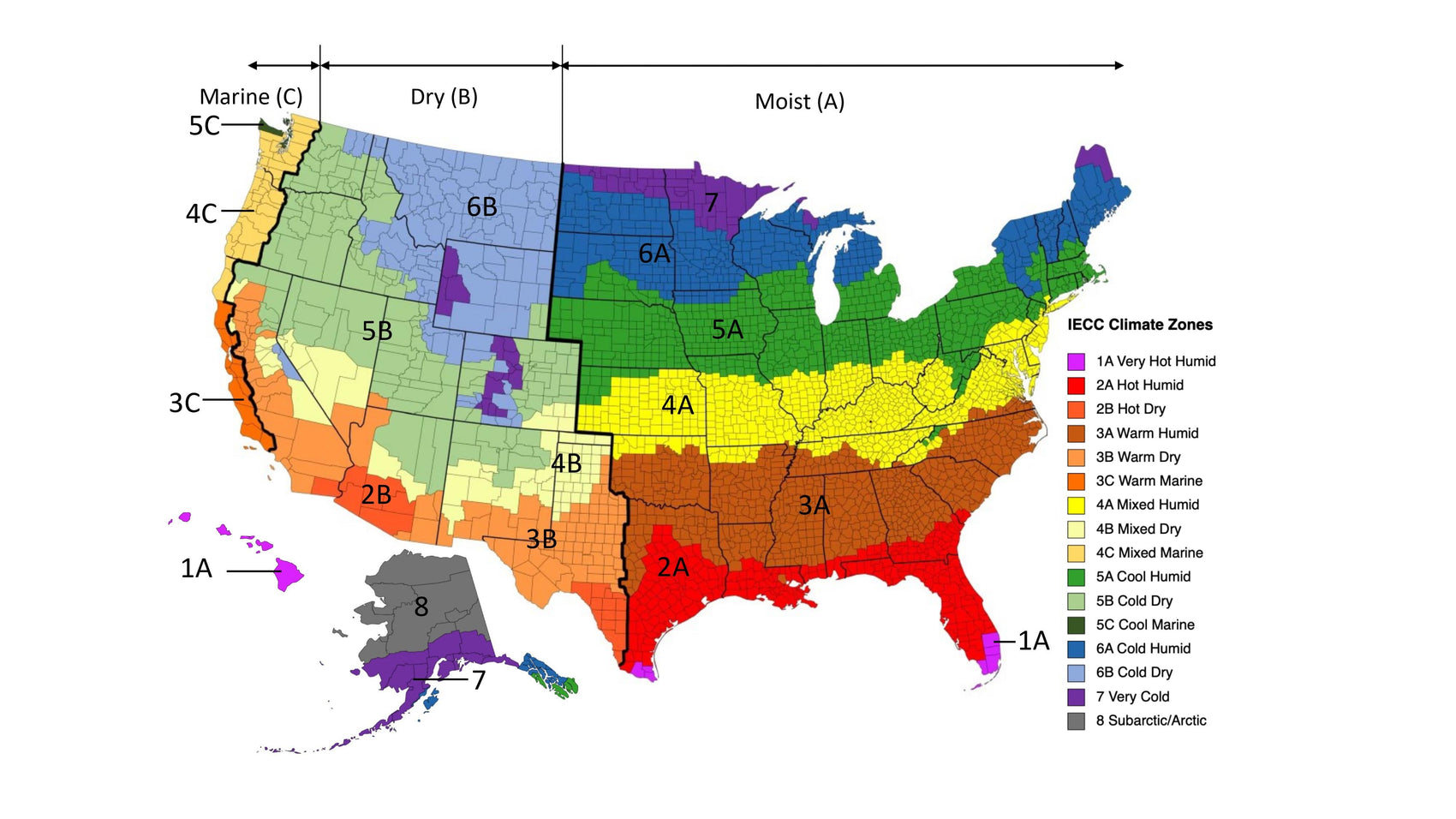

Spanning eight climate zones, from very hot and humid to subarctic, and desert to rainforest, North America presents widely varied demands on our building enclosures. Anecdotally, there is much written on assemblies in cold climates but not so about hot climates. And most of the literature today assumes foam will be the primary strategy for achieving a high performance.

Watertight & Airtight

The order of importance of a building’s assembly control layers are (1) water, (2) air, (3) vapor, and (4) thermal. Regardless of climate zone, homes should be watertight and airtight. ProClima’s exterior membranes (ADHERO, INTELLO X, and the SOLITEX MENTO options) are extremely airtight and watertight because they incorporate the monolithic TEEE film (see this blog post for more info).

For most of the building’s exterior you can rely on a ProClima membrane for the watertight and airtight control layers. There will be transitions for these control layers. For example, the windows are acting as all of the control layers of the assembly, so we need to properly integrate the control layers as we change material and/or plane. For these transitions we can rely on ProClima tapes and adhesives to stay airtight/watertight even as the building settles overtime. There are many stresses on these control layers, and we need our connections to flex with the building while holding a strong adhesive connection (see this blog post for more info).

A building assembly’s vapor control and thermal control are both climate zone specific.

Climate Specific Vapor Control

Assemblies rarely should include a true vapor barrier (vapor closed material [class 1 vapor perm]). There are locations where that’s necessary such as materials that are touching or below grade. Also, an exterior membrane on a flat roof or any horizontal surface where there could be standing water. High performance assemblies aren’t baked dry from oversized mechanical systems. We’re inherently limiting the energy passing through our assemblies by super insulating. High performance assemblies need to dry through diffusion.

For climate zones 1-3 the vapor drive is predominantly from the exterior moving towards the interior. The exterior side of the structure should be a class 3 vapor retarder (between 1-10 perms). Plywood is more vapor permeable than OSB. The Solitex MENTO membranes are more vapor permeable than the ADHERO membrane. For these climate zones ADHERO over plywood – or – Solitex MENTO over OSB is appropriate. We’re relying on the sheathing for the vapor control layer and utilizing the ProClima membranes because we’re prioritizing watertightness and airtightness.

For colder climate zones 5-8 the vapor drive is predominantly from the interior moving towards the exterior. The exterior side of the structure should be as vapor permeable as possible. Oftentimes the sheathing layer is still the vapor control layer, but there are vapor open sheathing options available (masonry sheathing for example) or creating a sheathingless assembly (LINK).

In climate zone 4 seasons are more even so oftentimes the exterior permeability is based on if the project is in the “humid”, “dry”, or “marine” zones.

Climate Specific Thermal Control

Thermal control is climate specific. The colder the weather the more insulation is needed. But warmer climates also need insulation – most homes have air conditioning now-a-days and there can still be a considerable temperature difference from the room temperature and outdoor ambient air temp.

There are two main high-performance approaches for thermal control. There’s one that focuses on exterior insulation. Oftentimes doing a dewpoint analysis to assess how much insulation is needed outboard of the sheathing layer to prevent condensation occurring on the interior side of the sheathing. The primary concern with this approach is that vapor closed or too vapor retarding (class 2) insulation is oftentimes used (see this blog post for more info). But this thermal control approach can be done with vapor permeable insulation such as doing an I-joist or Larsen truss assembly or using a vapor permeable fibrous rigid board insulation (ex. wood fiberboard, mineral wool or cork).

The other thermal control approach is to prioritize an interior air barrier so that you’re keeping the conditioned air within the conditioned space. And not allowing the conditioned air to meet the backside of the sheathing. Now exterior insulation is less (or not) necessary. The assembly can utilize a thick layer of fibrous vapor permeable and hygroscopic insulation. Insulation like cellulose that can act like a sponge and safely hold the moisture to dry through diffusion. The Intello Plus membrane even includes netting built-in to support the install of fibrous dense-pack insulation.

Vapor Intelligent Control

If the moisture risk of the assembly increases, then the vapor variability of the Intello membrane becomes key. A couple examples of moisture risk increases are (1) the exterior of the assembly is vapor closed (or too vapor retarding) or (2) maybe there’s not enough insulation to keep the wall’s interior finish (drywall or similar) surface temperature close to the building’s room temperature. These are risks because you can trap moisture by not allowing the moisture to diffuse properly or have an air meet a surface that has a large temperature differential, creating condensation. The Intello membrane is highly vapor variable, so it’ll never trap moisture and instead works with the natural vapor drive to steadily reduce the moisture content of the assembly (for more info see this blog post). But principally just having an interior air barrier is reducing a lot of risk (for more info see this blog post).

‘Phew’, it’s difficult to write succinctly about a holistic approach. If any of the info touched on in this article is confusing, then please reach out to the 475 sales team to discuss high performance solutions. 475’s sales team is available to discuss your projects and install details! In the meantime, here's a quick cheat sheet for control layer selection based on climate zone:

|

||||||||||||||||||||||||||||||||||||||||||||||||||