Creating Comfortable, Foam-Free, All-Electric Senior Homes In Ontario’s Ski Country

There are several hot topics we look out for here at 475: foam free building, Smart Enclosures, prefab manufacturing, and frack-free (all-electric) housing. This is a rare project spotlight that hits every nail on the head. They’ve managed to eliminate foam even from the foundation, they use a variation of our I-Joist Smart Enclosure details, they’ve carefully designed and built the pieces in their pre-fab shop, and they finish the building in a way that is ready for a low-carbon, resilient future. We’re very proud to get to work with this firm and see their work continue to advance and grow.

Simple Life Homes have been dedicated to building green from the start, making healthy homes for occupants and the earth. The mission hasn’t changed, as the approach continues to progress and grow along the way. Simple Life Homes is now focused on building prefabricated, panelized structures, using natural materials that capture and store carbon. With the recent urgent report produced by the IPCC, the call for action has become even more clear, and Simple Life Homes heeds that call.

Aging in Place with Comfort and Style

This project is being built in cottage country, Haliburton Ontario. Located a short drive from Sir Sam’s Ski Hill, set inside the Haliburton forest. The home was designed for retired living. A single-story, high performance home offers ability for aging in place with affordability in mind. The high performance design called for super insulated floors, walls and roof.

Foam Free Foundation

A 5’ Nexcem frost wall was built atop concrete footings, to support the structural prefab wall panels being used. This ICF product uses a mix of recycled wood and cement to form a block. This home utilized a 14” block with rock wool insulation totaling R-22.

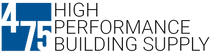

Layers of crushed stone were compacted beneath to the desired height. The next alternative solution used was 3 layers of rock wool. A semi rigid version of the typical rock wool batts, it has enough compressive strength to support a 4-6” concrete slab. The 3 layers total 3 3/4” and achieved R-15 beneath the slab. If insulation beyond R-15 is used, energy modelling shows diminishing returns for this location and climate. Above the rock wool insulation, a 10mil poly vapor barrier was placed down and all seams taped.

Lastly, a series of mesh reinforcing sheets are laid down to add strength to the concrete slab. Once the ground work is complete, 2x6 sill plates are set on the ice wall to receive the incoming prefab wall panels.

Simple Life Homes attempted to source high slag concrete to reduce the carbon footprint of concrete used during the project, but were unable to have it delivered for this particular project, so conventional concrete was used.

Assembly of the Prefab Wall

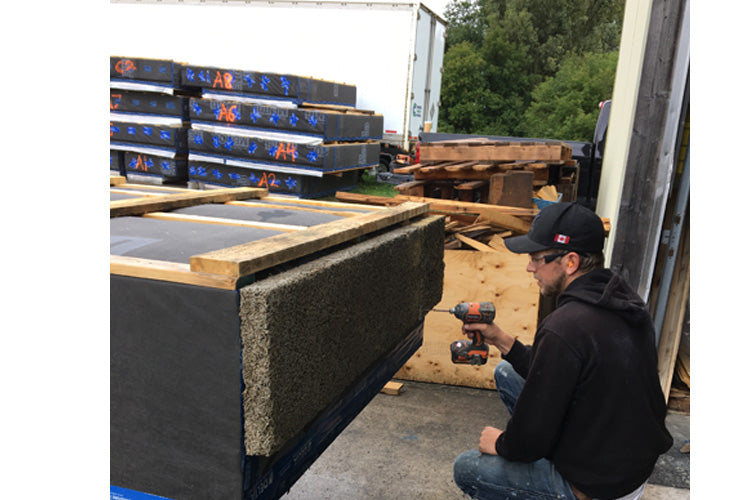

After meticulous planning and precision measurements are complete, the prefab parts are assembled piece by piece on the table. First, the structural 2x6 wall comes together. The INTELLO Plus interior airtightness layer + smart vapour retarder is applied to what will be the outboard side of the the interior studs, essentially becoming an integrated service cavity (for more on that concept see this post). Window and door penetrations are boxed out and taped with TESCON VANA, along with the seams of the INTELLO Plus. A 1.5” thick layer of wood fiber board insulation is screwed in to the studs as the next layer, followed by 12” TJI placed vertically, 16” on center. The exterior layer begins by wrapping the whole thing SOLITEX MENTO 1000, sealing the seams and penetrations again with TESCON VANA, and covering sills with EXTOSEAL ENCORS flexible, self-sealing, waterproof sill tape. A rain screen is created by first screwing 1x3 vertical strapping through the SOLITEX MENTO 1000, to the TJIs, then applying 1x4 horizontal strapping atop that. The wall then gets forklifted off the table, where a 1.5” thick Nexcem sheets is attached for an insect and water resistant sill plates. Panels are stacked in order outside where they get a recycled cellulose insulation injection from the top of the insulation bays, providing 12” of dense packed at an average of 3.5lbs / C.F. The brightly labeled walls are now ready to move to site.

Manufacturer’s note: Pro Clima’s recommended membrane of choice in the case of a dense-pack assembly without exterior sheathing is SOLITEX MENTO Plus. It has a reinforcement layer suitable for holding a high volume of dense pack material, and is ideal for blowing through on the exterior. Through a combination of skill, and planning Simple Life Homes gets away with using the non-reinforced SOLITEX MENTO 1000 in a way that avoids any ruptures due to dense packing. In other words, we love the work they do, but if you were trying this at home we recommend you use SOLITEX MENTO Plus. For more on membrane recommendations, see our recent WRB Cheat Sheet describing which exterior membrane should be used depending on project needs.

Simply Coming Together

The truck moves to site with its prefab wall cargo, and pieces go up one by one. Studs are used to stabilize each panel on the foundation before they are fixed in to place. Structural walls are joined, and the whole building comes together.

Sheathing-less truss roof

The roof is also a sheathingless assembly (the same manufacturer’s note from earlier applies - sheathingless roofs would normally call for SOLITEX MENTO Plus or SOLITEX MENTO 3000 Connect membranes). A set of trusses is assembled above the completed prefab wall system. Above the trusses, SOLITEX MENTO 1000 is stapled on, strapped with 2x2’s parallel to the truss top chords and 1x4 strapping perpendicular to truss chords 16” on center. A standing seam galvanized steel roof finishes off the top, fastened to the strapping beneath it. Below the trusses INTELLO Plus is stapled to the underside and strapped with 2x2s to form the ceiling where the drywall will be afixed. 24” of loose fill cellulose rides on top of the INTELLO Plus. Everything is sealed up and and attached to wall membranes with TESCON VANA tape.

By the time the assembly comes together it’s already ready for winter, keeping builders warms as the project continues. In the end this will be a comfortable, quiet, fully-electric home in anticipation of forthcoming clean hydroelectric power coming to the Ontario grid. It’s also set up to allow for future site generated power via photovoltaic panels. Its outfitted with a C-ERV “Conditioning Energy Recovery Ventilator” - combo ERV and heat pump. It also utilizes a 5 KW post-electric heater for back-up heating, LED slim lighting, induction cooktop, ventless heat pump dryer, and electric resistance hot water heater.

For more about Simple Life Homes and the incredible work they do, see their website, which includes their work with strawbale and earthen building materials utilizing INTELLO Plus and SOLITEX MENTO membranes for airtightness.