Installing exterior vapor retarding layers such as asphalt roofs, flat roof membranes and OSB sheathing can create challenging situations in well-insulated walls and roofs. However, such assemblies can be safely built and insulated when using a smart vapor retarder and airtight layer on the interior - even in colder climate zones (4 and up).

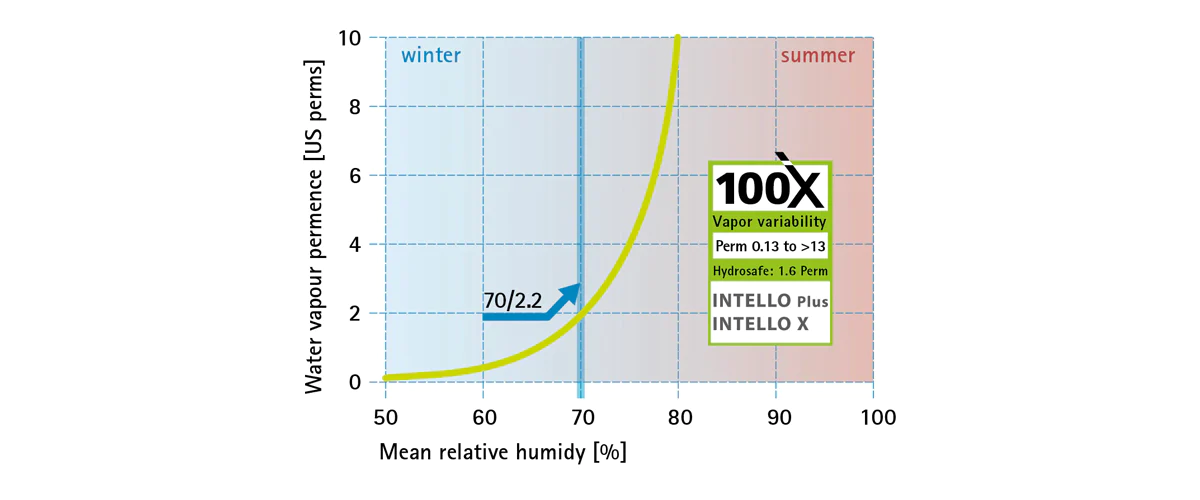

To make these assemblies as safe as possible, Pro Clima introduced INTELLO in 2006. INTELLO has a remarkable vapor variable range with a permeability spread of over 100 times (from 0.13 to more than 13.2 perms). This large vapor variable range not only performs well in the lab and in computer simulations (WUFI Pro), but has proven itself in many Passive House projects in North America after 475 began selling it 2011. We have supported foam-free construction through project consulting and monitoring - and have shared a great deal of data about the safety of such enclosures in blogposts (see references below).

Is the airbarrier HYDROSAFE?

Vapor retarding membranes have a complex job to perform. During the life of the building, INTELLO closes in winter to prevent wetting and opens in summer to allow inward drying - increasing drying reserves and making for a robust moisture safety buffer. This powerful dynamic is well understood.

But during construction there can be particular stresses placed on the membrane and assembly, typically not found once the building has become occupied. Mudding drywall, tiling or pouring concrete can lead to interior relative humidity levels near 90%! To make sure that the ingress of humidity is kept to a minimum in such situations, Pro Clima has developed the "HYDROSAFE rule".

HYDROSAFE RULE

The HYDROSAFE rule states, that to prevent moisture damages, when INTELLO experiences an average humidity of 70%, the perm rate of the INTELLO should not exceed 2.2. (At 70% relative humidity, INTELLO has a perm rate of 1.6, providing a strong safety buffer.)

70/2.2

This 70/2.2 reference point is critical in preventing construction site activity from placing potentially damaging moisture stress on the assemblies. Also, high interior humidity is always a risk when building airtight in winter months, even though we recommend to avoid it (this warning is also printed on INTELLO). Nonetheless, interior humidity can reach 90% for short periods of time. If the insulation and structure behind the installed INTELLO are then at 50% RH, the average humidity INTELLO experiences is around 70% RH.

Again, according to the HYDROSAFE limit, a smart vapor retarder at such climatic conditions (70%RH) should have at most a perm rate of 2.2 to prevent excessive moisture ingress. With INTELLO at 1.6 perms in that situation, ProClima's vapor variable membranes easily stay below the limit. As a result, the structure is safe and we prevent excessive wetting of the structure in winter weather. (See also "why the vapor curve matters").

Fast and wide opening in summer, with inward diffusion

It is then also important, when there is unforeseen humidity in the insulated enclosure, that we be safe. It is construction after all, and wet lumber and other materials often end up being used. Inward drying is crucial when humidity is pressed inwards in warmer weather. The faster the membrane opens up above the HYDROSAFE value (70%RH) , the better. As shown, INTELLO reaches a perm rate over 10 perms when RH exceeds 80%. Such high humidity values occur when assembly humidity is pushed inward by solar heat. This is also apparent when comparing ASTM E96 dry (<0.2) to wet cup results (>6 perms).

INTELLO's vapor variability has been independently confirmed in the DIBT certificate of INTELLO for externally vapor closed assemblies. ProClima's INTELLO Plus and DB+ are currently the only airtight and vapor control membranes that can be legally specified in Germany as a vapor variable retarder with its European Technical Assement (ETA) from DIBT.

Most importantly, we can also see that this vapor variability has worked reliably in built projects with moisture monitoring. For instance, the Maine Bayside project by Ecocor experienced unforeseen construction humidity in a foam free flat roof. But because of INTELLO's rapidly responding perm rate variability, the roof dried inward quickly in the first summer (June-Sept 2014). After that the assembly has stayed safely below 15M%. See the following blog post for more details: INTELLO responds to unforeseen construction moisture (proof is in the logged data).

What about other "smart" vapor retarders?

Other smart vapor retarding membranes or intelligent vapor control layers claim to provide the same safety. However, they fall short when it comes to both vapor control performance and air barrier system durability. (Their technical support is weaker too!). These are all important factors when specifyingvapor variable membranes to make your foam free assemblies safe and durable.

Below we list some disadvantages of INTELLO's competition:

- Certainteed Membrain opens up far too early, with more than 5 perms at 55%RH. These conditions often occur in airtight houses. To meet the HYDROSAFE limit would require less than 2.2 perms at 70% RH.

- Siga Majpell is called "intelligent moisture management", even though it has a fixed perm of 0.68 in EU testing (EN 1931 - Sd value of 5m). The product is portrayed on their website (2017) as: "particularly diffusible". But it also states that "it provides utmost safety, because it protects the building against excessive moisture penetration in construction phase". Majpell appears to make contradictory claims of both fixed permeability and intelligent properties.

- Siga Majrex was introduced in 2017, self-described as retarding inward vapor drive less than outward vapor drive. The perm rate (as per EN 1931) is reported to be directional in the test conditions (test conditions are 0% one side, 75% the other side). When Marjex is exposed to that humidity it ranges from 0.68 perm (same as Majpell inwards) and 0.23 perm in the other direction (outwards). In comparison, INTELLO is 0.44 perms at those conditions. However, when tested to EN 12572 for vapor variability, Majrex only opens up to 4.25 perm in extremely damp conditions (90% RH). And 4 perms is per the International Building Code a semi-permeable material, ie a class III vapor retarder, so not all that open and "permeable". As a result Majrex doesn't come close to the factor 100x variance of INTELLO, which opens up to >13 perms and retards in dry conditions down to 0.13 perms.

When you add up INTELLO's EN 12572 safety margins, its DIBT approval and HYDROSAFE value of 1.6 - it clearly shows why builders have been able to depend on the ProClima products for more than two decades in foam free construction. Choose INTELLO for:

- eight critical and common foam-free assembly situations - that can be safe from mold and moisture damage, and durably airtight with TESCON VANA's 100 year tested bond

- for expert WUFI Pro support by certified WUFI ORNL instructor Floris Keverling Buisman

- for dependable EN, ASTM and CAN/CGBS testing of all crucial properties for code compliance (and beyond)

- for full technical support on your building projects, including code interpretation assistance and WUFI reports for 475 Advance members, architects and building inspectors

- 10 year ProClima warranty - comprehensive, fair and transparent (note, not a limited warranty with fine print that only provides replacement product)