Use the Weather Resistive Barrier Cheat Sheet to choose from a variety of SOLITEX WRBs

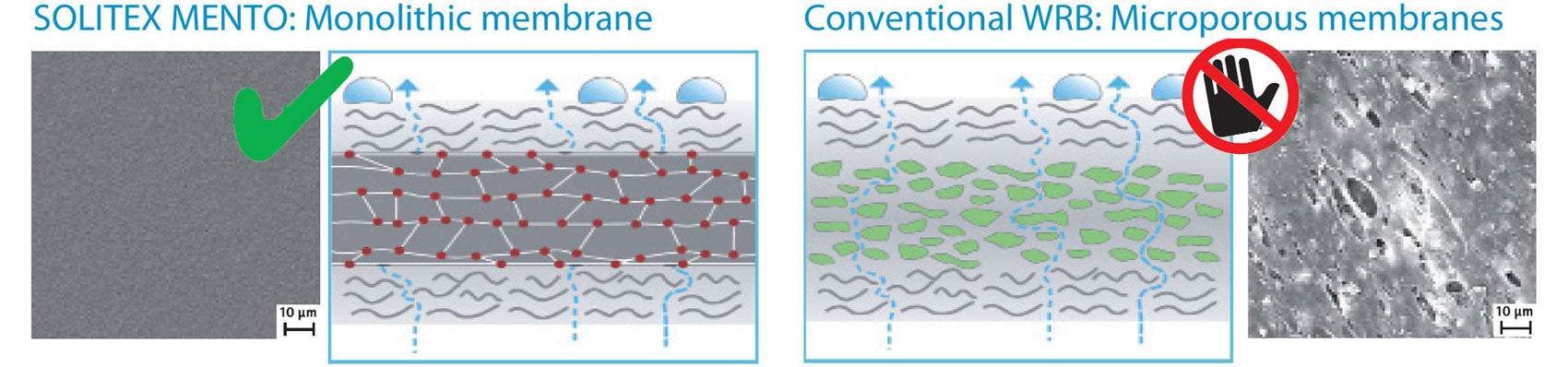

| SOLITEX actively vapor open function, purely diffusion driven (left) Microscopic image of TEEE membrane (right) | Conventional WRB vapor open function (convection driven) and microscopic image of micro-porous membrane (on right) |

|

|

By being porous, perforated or stretched, these materials are not 100% airtight. They are therefore vapor open because air and water-vapor molecules, driven by convection, leak through the micro-pores. Since the pores are quite small - nanometer scale - a relatively high vapor pressure differential is required for vapor to actually dry outwards through the pores. This is true even if the actual perm rating (per ASTM E96B) is high, which could be the case because the pores are big/perforated. If you can easily blow through the membrane when placing it over your mouth, the pores are probably large - very vapor open, and not very airtight.

Through active vapor diffusion, the SOLITEX MENTO membrane remains dry (left). In the same roof the microporous membrane causes condensation to form, because passive vapor openness is not sufficient for outward drying (right)

The example above shows that actively vapor open SOLITEX MENTO membranes remain dry even when large amounts of humidity enter a roof enclosure with compromised interior airtightness. However, the conventional passively vapor open membrane in the same building is showing condensation - because water vapor wasn't transported fast enough, casuing a layer of condensate to build up. It looks like the membrane leaks, but the moisture is actually just interior humidity.

How is a vapor open membrane waterproof?

A micro-porous or perforated membrane is "waterproof" because the surface tension in liquid water holds the drops together and prevents water beads from passing through the membrane. But if that tension is broken by oils (found in wood preservatives), wood tannins, soap and dirt, the waterproofing becomes compromised.

Lab test water column (DIN EN 20811) on conventional WRB. The right half was treated with oil, rendering it leaky.

In contrast, the monolithic film in SOLITEX MENTO is completely waterproof. In the lab tests shown above and below you can see the effect of applying oil to membranes before testing the water column (EN 20811/AATCC TM 127) of each membrane. The conventional membrane leaks at low water pressures, while the SOLITEX MENTO membrane stays dry at a much higher column (notice the difference in bulge). This demonstrates that the waterproof qualities of the TEEE work even when exposed to oil.

SOLITEX MENTO uses monolithic membrane and if waterproof (DIN EN 20811) up to lab test limitation of 32' (10m). Right side is coated with oil without effect on waterproofness.

Preventing windwashing

SOLITEX MENTO's monolithic membrane is also absolutely wind & airtight . ASTM E2178 test results show that the material is so airtight that it exceeds the capabilities of the lab calibration - and goes above and beyond the AABA requirements and ICC-Accepted Criteria 38 for WRBs. The Pro Clima WRB/roof underlayment system offers the ultimate protection against wind-washing of insulation when taped with TESCON tapes and following the other instructions found on SOLITEX MENTO product pages.

A number of projects using Pro Clima exterior membranes have demonstrated airtightness numbers below 0.6ACH50 - prior to interior airsealing.

Three layers - each with its own function

All Pro Clima WRB membranes are multi-layered products, with each layer having specific properties to assure the product offers first class performance during installation and the life of the building. The top layer serves as a protective cover made with a PP microfiber fleece. This offers the weather/UV resistance needed for both roofs and walls:

-

SOLITEX MENTO 1000", INTELLO X: 3 months exposure

- SOLITEX MENTO Plus, SOLITEX MENTO 3000 Connect: 4 months exposure

- ADHERO: 6 months exposure (walls), 3 months exposure (roofs)

- SOLITEX MENTO 5000 Connect: 6 months exposure

- SOLITEX FRONTA QUATTRO: 6 months exposure with ongoing exposure of up to 3/4" gaps in open-joint siding

When SOLITEX MENTO, or INTELLO X is used as roof underlayment, the top layer offers slip resistance, while also protecting the TEEE layer below.

Build-up of a Pro Clima's truly high performance WRB and roof underlayment

The TEEE functional layer is located in the middle of each product, providing the actively vapor open AND waterproofing properties of the material. It was specifically developed for this purpose in SOLITEX MENTO and FRONTA QUATTRO. The other membranes employ other monolithic materials, for their specific uses/vapor profiles.

Showing the 3 layer build up of SOLITEX MENTO 1000 (via BLDGTYP.com)

The bottom microfiber fleece protects the TEEE layer above against damages from installation over rough cut lumber and allows it to be pulled over structural members.

*TEEE: Thermoplastic Elastomer Ether Ester – is a material that combines the flexibility of rubber with the strength of a membrane, resisting tears, abrasion and corrosion. It also has good resistance to oils, fuels and chemicals.

Find the exterior membrane for your next project

This chart is your cheat sheet to each exterior membrane and its use. Click names to navigate to each page where you will find details, pricing, installation guides, spec sheets, and more. All of these materials are stocked in the US and ship in 1-3 business days. Note that “Roof” refers to pitched roof applications. We do not carry any membranes for flat roof applications at this time. Read more about our advice for flat roofs here. Please consult a 475 team member if you have any questions. We’re here to help!